"UK's largest independent UV weather testing facility"

+44 (0)2380 580240

UV Weathering

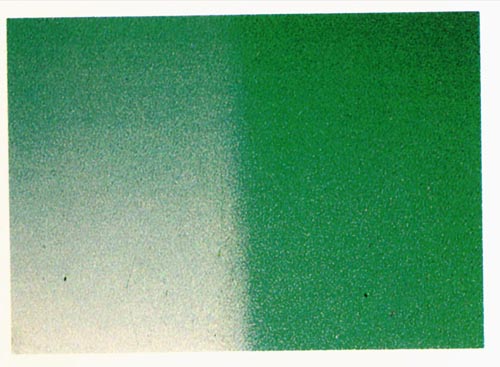

We offer a wide range of accelerated UV weathering test capabilities. Any product that is designed for outdoor use, intermittent exposure to natural light, or even indoors behind glass or exposed to fluorescent light should undergo some form of UV weathering testing. UV weathering can result in colour loss, cracking, crazing, chalking, hazing or complete product failure in relatively short periods of time. We have over 15 years of UV weathering testing experience.

Accelerated UV weathering reproduces the damaging outdoor conditions in a controlled laboratory environment. The exposure conditions use a combination of intense UV, heat and moisture to produce an acceleration factor. This reliably produces results after only days or weeks in the laboratory which are equivalent to months or years of outdoor exposure.

Accelerated artificial weathering is particularly useful for determining the inherent photostability of a material or the effectiveness of any UV stabilisers added. The equipment can also determine the retention of aesthetic properties such as colour, surface finish, gloss, susceptibility to cracking, crazing or hazing. Manufacturers and finishers in the coatings and painting industry, fabrics, plastics, rubbers and sealants industries and the marine and architectural field find UV weathering testing invaluable for quality assurance and materials certification and comparison.

On the left of this page you will find useful links that will give more detail about the UV weathering tests or UV degradation of materials. Equally we are more than happy to discuss any concerns that you have about your product and whether UV testing is relevant to your product.

There are several methods for conducting acclerated UV weathering of materials. These include:

1) Outdoor exposure in sites like Florida and Arizona

2) Fluorescent bulb type tests (QUV)

3) Xenon Arc type tests.

We can offer you both fluorescent bulb type testing and xenon arc type testing. However, unless your specification dictates the use of xenon arc we would suggest fluorescent bulb type testing as the first option. This is often more cost effective and flexible and also provides the most accurate simulation of the UV spectrum. See our other sections for more detail.

A typical cycle will expose samples to a combination of UV, heat and a moisture condensation phase. The specific cycles and exposure conditions are detailed in the relevant standards. We can operate to most of the ASTM, ISO and SAE standards. However, we can also create custom programmes for your particular products if required. Most European clients will test in accordance with ISO 4892-3, ISO 4892-2 & 11507 whereas most American clients will test in accordance with ASTM G154.

Ultra violet (UV) light accounts for around 5% of the sunlight received on the earth's surface (see solar irradiance spectrum below) and falls in the waveband 100-400µm. There are three UV bands (A, B and C) with wavelengths 400-320µm, 320-280µm and 100-280µm respectively. UV radiation interacts with bonds in polymers (plastics & rubbers) which can lead to degradation of the polymer chains and most damage occurs in the 290-400µm range. This degradation can lead to cracking, chalking, colour changes and loss of mechanical properties, all of which must be monitored if the polymeric material is destined for an application outside.

Some recently tested products include: cables, outdoor seating, labels, telephones, webbing, artificial ice rinks, plastic decking, door furnishings, childrens toys, drug delivery devices, adhesives and coatings and many more.

Analytical Services:

We offer a number of services that support the UV weathering of samples including colorimetry to quantify any colour changes in samples caused by testing. We also offer mechanical testing services; please contact us to discuss your requirements.

© Materials Technology Limited, Registered in England & Wales No. 05764619, Contact +44(0)2380 580240